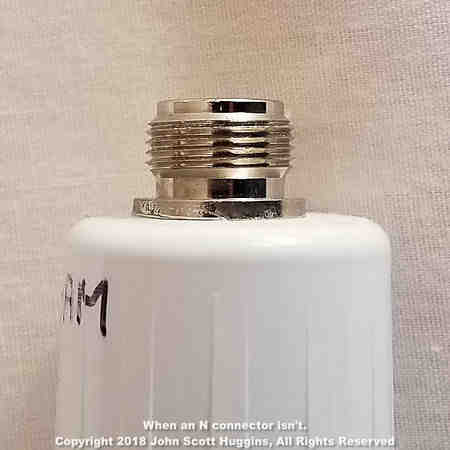

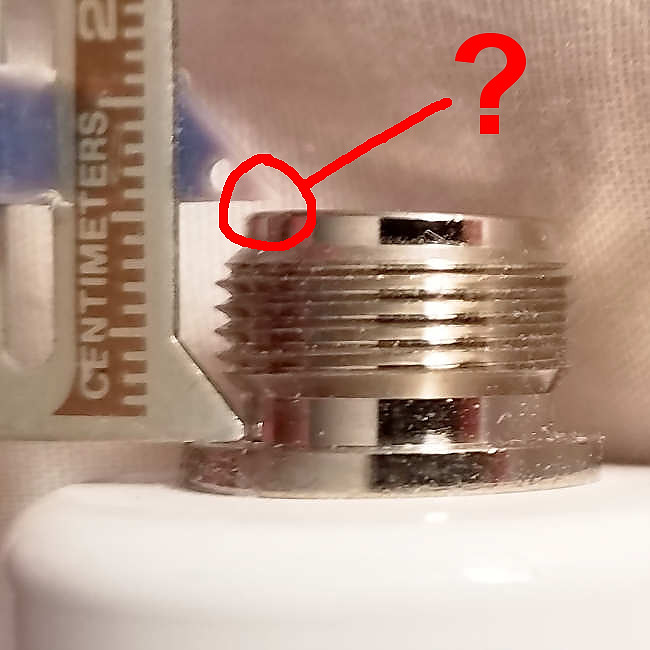

This is an N connector… or is it?

Looks innocent enough right? It’s actually quite handsome on this plastic cap to serve as the feed point of a commercial antenna. The devil is in the details though as we attempt to attach a connector.

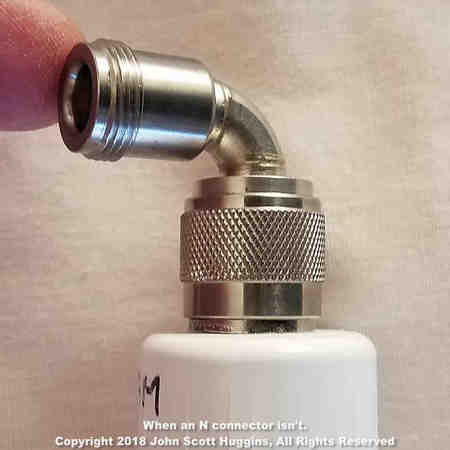

Let’s try two N male example connectors

Pictured above are two N connector adapters chosen randomly from some container. Let’s try the SMA-N adapter first.

Some N connectors engage adequately

Let’s hand tighten it.

Hmmm, this particular adapter’s mating coupling nut bottoms out on the shoulder, but does engage the internal N connection and o-ring seal well enough to prevent the inner portion from easily spinning around.

Some N connectors don’t engage adequately

Let’s hand tighten it.

This particular adapter’s mating coupling nut bottoms out on the shoulder, but does NOT engage the internal N connection and o-ring seal well enough to prevent the inner portion from spinning around with the slightest touch.

Loosey Goosey N connector engagement

In the case of the elbow, the mating coupling nut bottoms out without providing adequate compression to the N connection interior. Thus the front face of the N bulkhead doesn’t compress against the elbow’s o-ring seal. The elbow spins freely. This is not likely what was meant by the designers of the N connector… and no… the N connector was never meant to be a rotational coupling system.

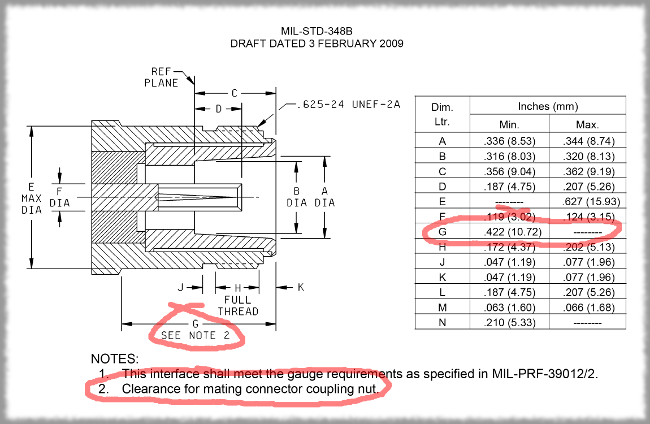

So what’s wrong with this N bulkhead connector?

Either the mating coupling nut is too long or the N bulkhead distance between the front face and shoulder is too short. Let’s consult MIL-STD-348 from the annals of time for guidance on what the N female is suppose to look like.

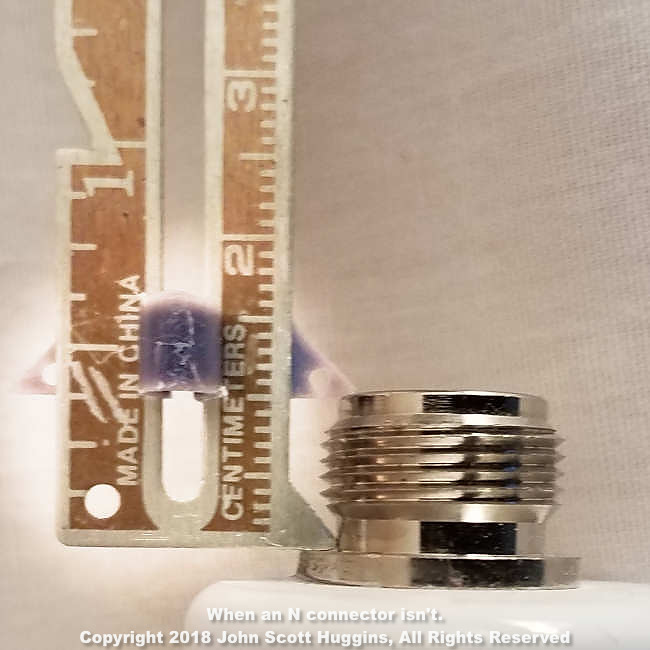

Let’s measure the N bulkhead’s dimension G

Well well… one centimeter exactly. Looks like the maker of this particular N bulkhead rounded 10.72 mm down to an even 10. Looks like they goofed big time. Rounding up to 11 mm would be perfectly fine. Or perhaps the designer paid attention to dimension J+H+K in the specification’s dimensions without noticing G. Hard to say.

Let’s examine what 10.72 looks like on the above connector…

This is a sewing tool, but a fisherman’s ruler it’s not so we can have some faith in what we see above. That little gap circled in red highlights what a difference less than one millimeter can make.

Pedigrees matter

Unlike the long extinct governing standard for the UHF connector, the N is one of many post WWII connectors fully described in active specifications, notably MIL-STD-348. When we opt for an N connector on an antenna product like above, we expect a certain quality about it. Lucky me I guess for purchasing this antenna to stumble onto such a problem in the supply chain.

Not the antenna maker’s fault

It’s important to realize this deviation from the N connector is NOT the fault of the antenna manufacturer. They have the same expectation of N connector pedigree as any connector purchaser. If they buy an N bulkhead for their product, they should receive one that will properly mate with any other N connector.

Blame shifting

It’s interesting to note the reaction of some when they realize their product has a bogus part in its design. This is the reaction I received from one such manufacturer.

I know you expect Mil Spec quality or even Space Spec quality, but we are not that.

Allow me to ask the obvious question. If you are not using the interface specification that makes N connectors mate with each other, what are you really trying to say here? Allow me to translate the above to the, I’m sure, unintended meaning…

I know you expect our N connector to mate with other N connectors, but what’s a mm between friends.

It’s everything man… everything. Are you really telling me how tightly a connector mates isn’t important? This connector flaw isn’t your fault, but now that you know, it is on you to fix the parts supply problem with an N bulkhead that meets the 10.72 mm coupling nut clearance along with everything else the specification mandates.

Dé·jà vu

Being in the engineering biz for a few decades brings back a recurring theme during many a requirements management meeting. One superb example is projects for items powered by vehicular power systems. My instant reaction is to apply the various notions detailed in MIL-STD-1275 – CHARACTERISTICS OF 28 VOLT DC ELECTRICAL SYSTEMS IN MILITARY VEHICLES. I’d receive instant pushback with the typical…

But John, we aren’t designing military spec. equipment for this particular project.

Whereupon I respond…

You don’t understand. 1275 isn’t teaching us how to design mil-only systems, it is teaching us how vehicular power systems actually are with regards to surges, spikes, drop outs, etc. You’re learning how to make our product work on any and all vehicle power systems, not just military vehicles. Ignore at your peril.

We had one supplier of a vehicle computer system proudly proclaim compliance with the typical 24 volt vehicle power system with his stated upper limit of 28.5 volts. Never mind the charging voltage exceeds this and spikes come in a 50+. Fail. I go into this topic more here.

The point of all this is standards are there to make things work together, not to make our lives difficult. Ignore at your peril.

Anyway, enough of that… back to connectors…

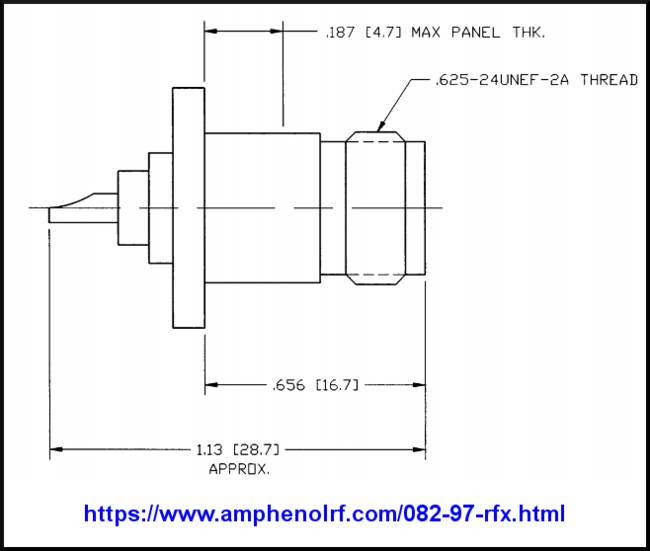

Amphenol – a good example

Amphenol is my goto supplier for most of my connector needs. I seriously doubt a vendor of such quality will ever manufacture N connector components that violate MIL-STD-348. Let’s look at one flange bulkhead example and check their math.

Another example

A member of my local ARC shared his frustration with the N bulkhead connector on his Times Technology T101 antenna analyzer he alleges has a “G” dimension of 10.1 mm… well short of “N” compliant. He’s not sure if this is causing his misconnection issues, but the alleged short “G” length makes one wonder what else might be out of spec.

Summary

Standards matter… A LOT! Breaking an interface standard is, perhaps, the most obvious and easy to spot issue, but once broken one has to wonder if the makers ignore other dimensional constraints. Blatant ignorance thus confirmed, one next must assess if the performance dictates spelled out in the related performance (MIL-PRF-xyz) standards referenced by MIL-STD-348 may have been leisurely followed.

How the N connectors we purchase are manufactured and how we assemble them into our products (like the panel example above) must all comply with the dictates of MIL-STD-348 or equiv. Scrimping on any parameter deviates from the designers’ intent. Is a bulkhead connector with N features and only a 10 mm coupling nut clearance an N connector? No it isn’t by definition and, by my example above, demonstration.

Conclusion

Unfortunately we live in a world where charlatans exist in our supply chain. I don’t believe the designer of the errant N bulkhead meant any harm by rounding 10.73 mm down to 10 mm, or ignoring dimension G altogether, but that small error makes all the difference in actual use. Let’s not sugarcoat this too much… it is a design screwup. For the moment, there are just two known victims: the maker of the above commercial antenna using the errant N connector and me as purchaser of the product. Hopefully readers of this article won’t be the next victim.

Vigilance is key. Buyer beware. I stick with Amphenol products purchased from listed Amphenol vendors and worry not.

References

- RADIO FREQUENCY CONNECTOR INTERFACES FOR MIL-DTL-3643, MIL-DTL-3650, MIL-DTL-3655, MIL-DTL-25516, MIL-PRF-31031, MIL-PRF-39012, MIL-PRF-49142, MIL-PRF-55339, MIL-DTL-83517 (B with change 3 ed.). US DOD. 2017-01-22.

- Amphenol N-Type Straight Solder Jack, Solder Cup, Panel Mount, 50 Ohm Part Number 082-97-RFX.

I have a pretty good idea of which antenna manufacturer that is, but I'm not going to name names here. It's really easy for anyone to unknowingly pay good money for bad parts. I work for a company that searches the Internet for counterfeit products, and there are is no shortage of them out there. This connector could have been just a poorly made connector, or it could have been labeled as Amphenol and sold on eBay for a premium to an unsuspecting buyer.

If you get a bad connector, you may have a bad day. But, beware even more of counterfeit products that can kill you. https://www.youtube.com/watch?v=QS6ywFGcLSk

No need since the antenna manufacture is just as much a victim.

Humbling video.

I bought a super duper Times Technology T100 VHF antenna analyzer with fantastic credentials. $200

Guess what? The N-fitting on the instrument fails to connect to many of the N coax connectors that are plugged into it.

Result a plethora of 99.6 SWRs. What to do?

No good tightening the thread – it just doesn't connect.

Neil, AB4YK.

My guess is the connector is too short, but sometimes these analyzers have a limit on how long a cable can be before the delay of the reflection misses the gate.

Thanks for this write-up. I was searching the interwebs to try and determine if there was another N spec which had a 10mm interface. This answers my question.

Much appreciated

Craig